01

The nature of bolted connection - preload

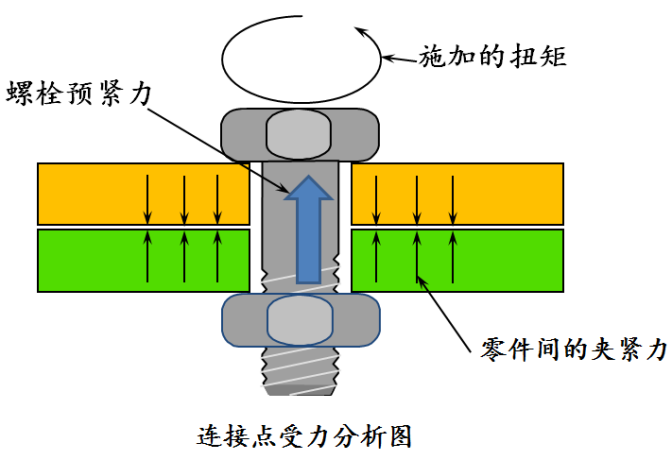

The bolt-nut connection is to make the nut rotate relative to the bolt by applying torque, compress the connected part by using the influence of the thread rise Angle, and at

the same time, the thread itself extends to produce pre-tightening force. The pre-loading force will make the connected part form a clamping force, the clamping force multiplied

by the friction coefficient between the parts, while considering the number of bolts and the number of faces connected, you can get the anti-slip ability of the part. At the same

time, in order to prevent the opening of the part, sufficient preloading force is also required.

The core essence of bolted connection is to obtain the clamping force required by the joint to meet the working load through calculation or measurement, and then make

the pre-tightening force provided by the bolt greater than this clamping force through tightening process.

The simplest way to tighten the bolt connection is to tighten the torque method, and how much torque is appropriate for the torque method? This is a common concern,

at the same time, also see often have a message to ask. To this end, today to introduce the simplest torque method to determine the tightening torque method, by looking

up the table to determine the tightening torque size of a common specification

02

The applied tightening torque is divided into three parts

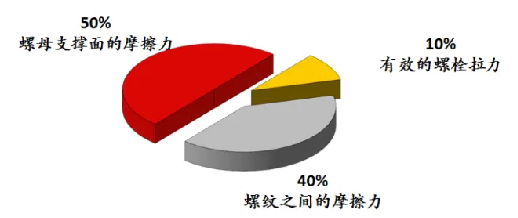

The bolt tightening torque is divided into three parts, which is what we often call the 5-4-1 principle:

1) The torque part of the pre-tightening force, which accounts for about 10% of the entire tightening torque;

2) The torque part to overcome the friction of the bolt thread, which accounts for about 40% of the entire tightening torque;

3) The torque part that overcomes the friction of the bolt head/nut support surface, which accounts for about 50% of the overall tightening

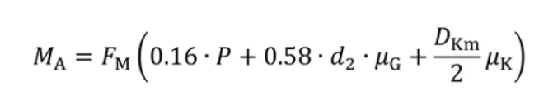

This proportional distribution can be analyzed and calculated using the torque calculation formula of the VDI 2230 standard:

0.16PFM is the effective bolt elongation force;

0.58μGd2FM is the friction between threads;

Dkm μK /2FM is the friction of the support surface.

Due to the relatively complex calculation of VDI 2230, in order to quickly know the tightening torque of common specifications bolts, it can be determined by the following

method, without the need for accurate calculation, you can reach the desired tightening torque value, and the result will not have a large deviation.

03

Fast determination of tightening torque

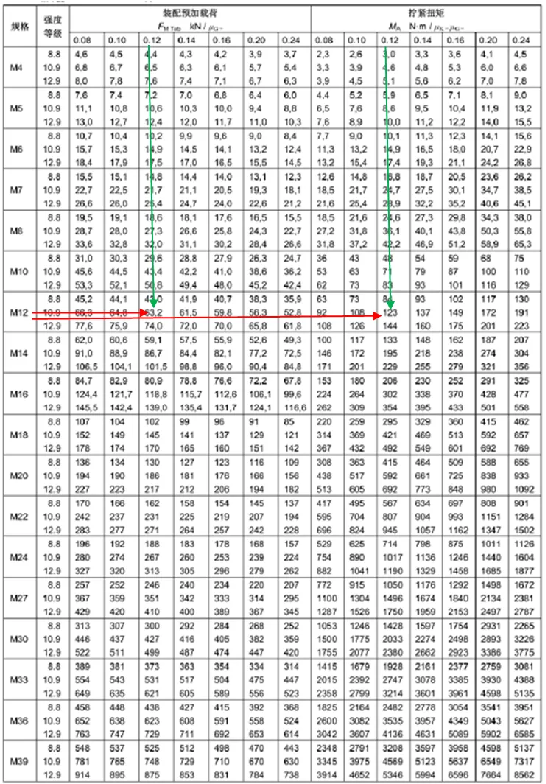

1, hexagonal head and hexagonal cylindrical head bolt coarse thread torque determination

The torque tightening torque for hexagon head bolts and hex head cylindrical head screws meeting GB/T 5782 and GB/T 70.1 standards can be quickly determined by the

following method.

A

Confirm the minimum friction coefficient of the bolt (generally according to this method to query the tightening torque, it is considered that the thread friction coefficient

and the support surface friction coefficient are the same), such as the minimum friction coefficient of the batch of bolts is 0.12, and the thread specification is M12-10.9;

B

According to the following table, it can be found that the maximum assembly preload of bolts with thread specifications M12-10.9 when the friction coefficient is 0.12 is 63.3kN

(the so-called maximum assembly preload at this time is actually the preload under the minimum friction coefficient of thread with 90% yield);

C

According to the minimum friction coefficient of 0.12, it is found that the maximum assembly torque of M12-10.9 bolts is 123Nm;

D

According to the torque tolerance required by the actual design, for example, the torque tolerance of the conventional bolt is ±10%, that is, about 12Nm, so the maximum tightening

torque is 123Nm, the tolerance is 12Nm, and the nominal tightening torque is 111Nm, so the tightening torque can be set to 111Nm±12Nm.

Therefore, through the above method, the tightening torque of these bolts under different performance levels and different minimum friction coefficients can be found according to the following table.

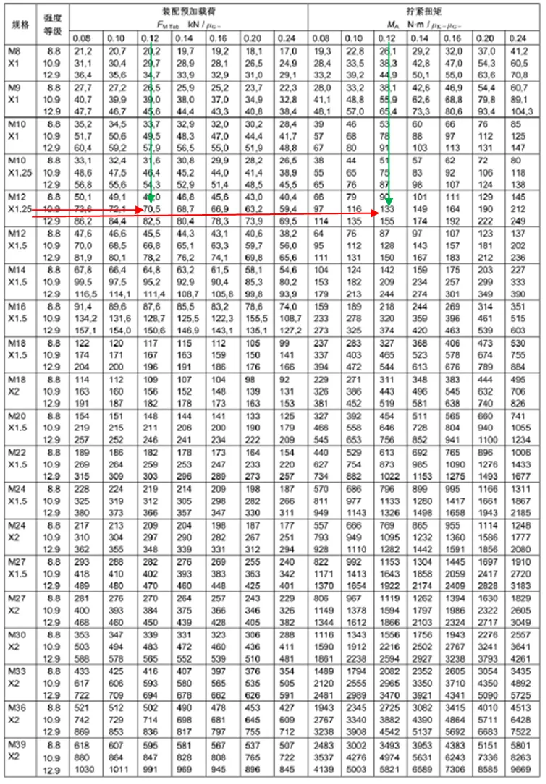

2, hexagonal head and hexagonal cylindrical head bolt fine thread torque determination

For meeting GB/T 5785, GB/T 70.1 (note that the normal GB/T 70.1 standard is coarse thread, but some companies require other dimensions are the same, only the thread is

changed to fine thread) standard hex head bolts and hex head screw torque method tightening torque can be quickly determined according to the following methods.

A

Confirm the minimum friction coefficient of the bolt (generally according to this method to query the tightening torque, it is considered that the thread friction coefficient and

the support surface friction coefficient are the same), such as the minimum friction coefficient of the batch of bolts is 0.12, and the thread specification is M12×1.25-10.9;

B

According to the following table, it can be found that when the friction coefficient is 0.12, the maximum assembly preload of the M12×1.25-10.9 bolt is 70.5kN (the so-called

maximum assembly preload is actually the preload under the minimum friction coefficient of the thread with 90% yield);

C

According to the minimum friction coefficient of 0.12, it is found that the maximum assembly torque of M12×1.25-10.9 bolts is 133Nm;

D

According to the torque tolerance required by the actual design, for example, the torque tolerance of the conventional bolt is ±10%, that is, about 13Nm, so the maximum

tightening torque is 133Nm, the tolerance is 13Nm, and the nominal tightening torque is 120Nm, so the tightening torque can be set to 120Nm±13Nm.

Therefore, through the above method, the tightening torque of these fine thread bolts under different performance grades and different minimum friction coefficients can be

found according to the following

Is it very easy to determine the tightening torque of a standard bolt?

For the tightening torque of some flange face bolts, because the supporting surface diameter of the flange face bolt is larger than the supporting surface size of the standard

hexagon head bolt, in principle, the twisting torque of the flange face bolt will be higher than the tightening torque in the above table, but in general, the deviation is not too

large, and the flange face tightening torque can generally be determined by referring to this table.

15061878696