In engineering and construction, bolts play a crucial role, and their preload and clamping force are the core parameters to ensure the reliability of the connection. However, in practical application, people often have a deviation in understanding and application of these two concepts.

Today, we will discuss and clarify these two concepts, and explain their importance in practical applications, and carry out specific analysis through the example of 10.9 class bolts of M8×25.

01

The pre-tightening force of the bolt

The pretension force is the internal tensile force generated by the bolt during tightening, which is related to the tightening torque, bolt material and friction force. The calculation of preload usually needs to consider the yield strength, safety factor and nominal cross-sectional area of the bolt material.

02

Clamping force of bolt

The clamping force is the compression force generated between the connecting parts after the bolt is pre-tightened, which ensures that there is sufficient contact area between the parts to transfer the load. The clamping force is affected by the preloading force and the connection structure.

03

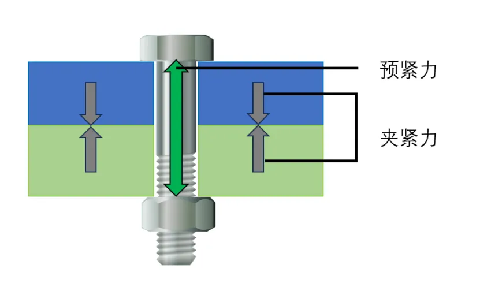

Relationship between preloading force and clamping force

The clamping force is derived from the preloading force, but they are not exactly the same. The clamping force is not only affected by the preloading force, but also related to the geometrical structure and material properties of the connecting parts.

In the absence of external loads, the pre-tightening force of the bolt is the internal tensile force stored through its elastic deformation during the fastening process, which is completely converted into the clamping force applied to the connected part. Therefore, in the absence of external load, the pre-tightening force of the bolt is equivalent to the clamping force acting on the connecting parts.

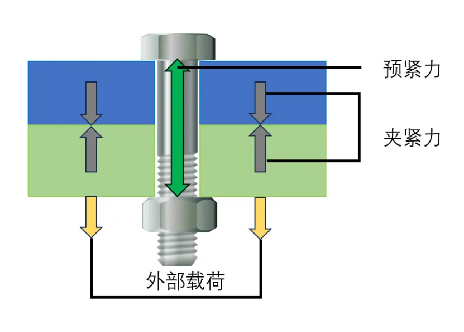

When bolts and connectors are subjected to load, they will undergo elastic deformation. If the external load is within the elastic limit of the bolt material, the deformation of the bolt will absorb part of the load and avoid all of it being superimposed on the preload. Therefore, although the total load on the bolt may exceed the sum of the preload and external load, the clamping force (that is, the actual pressure) felt by the connector may be somewhat reduced.

When the external load is lower than the bolt preload, the bolt will not deform significantly, and the preload will remain unchanged, but the clamping force will be reduced. Conversely, if the external load exceeds the preload of the bolt, the bolt will further stretch, possibly causing the connector to separate and lose the clamping force. In this case, the stability of the connection between the bolt and the connector is threatened.

If the external load greatly exceeds the pre-tightening force of the bolt, the clamping force may drop to zero, causing the loss of contact force between the connectors, resulting in separation. At this point, the main force maintaining the connection is no longer the pre-tightening force of the bolt, but the externally imposed load. Therefore, bolt connections must be designed with the maximum possible external load in mind to ensure the integrity and functionality of the connection.

04

Causes and effects of misuse

In practical applications, preload and clamping force are often confused, the main reasons are:

Measurement challenge

The measurement of preload depends on the accurate measurement of bolt elongation, while the direct measurement of clamping force is more complicated.

Design simplification

In order to simplify the design process, the subtle difference between the preload and the clamping force may sometimes be overlooked.

Understanding difference

Some engineers may not fully understand the difference between the two concepts.

A clear distinction between these two parameters is essential to improve the safety, economy and performance of bolted connections.

security

The wrong preload setting may cause the connection to fail and may even cause a safety accident. For example, too high a preload may cause a bolt to break.

economy

Proper preload helps to extend the service life of bolts, reduce maintenance costs, and thus improve economic efficiency.

Performance improvement

Accurate preloading and clamping forces can improve the overall performance of the connection, including reducing vibration and noise and increasing stability.

Therefore, engineers and technicians need to have a clear understanding of these two concepts and apply them accurately to ensure the reliability and safety of the structure when designing and applying bolt connections.

05

Example analysis: M8×25 class 10.9 bolt

In order to more specifically demonstrate the difference between preload and clamping force, take a common bolt specification - M8×25 class 10.9 bolt as an example to analyze the difference between clamping force and preload force under different working conditions:

Inspection specifications:

Bolt diameter D=8mm, length L=25mm; The material is 10.9 grade steel, yield strength =1090MPa.

5.1 No external load

Preload Fp calculation formula:

Fp = A×Rm/n

Among them:

A is the bolt cross-sectional area π× D2/4 = 50.27mm2;

The safety factor n is 0.8;

Then Fp = 50.27×1090/0.8 = 68600N;

At this time, the clamping force Fc = Fp = 68600N.

5.2 External load within the elastic range, such as F=20000N

Total load Ftotal = external load F+ preload force

Fp = 20000+68600=88600N

Assuming the elastic modulus E = 210GPa, the deformation δ = Ftotal/AE = 0.1mm is obtained by simplified spring formula.

Due to the introduction of 0.1mm relaxation due to deformation, the clamping force is reduced to Fc = 68600-20000 = 48600N.

5.3 External load F=30000N(lower than preload)

Preload remains unchanged, Fp=68600N;

But the clamping force decreases, Fc=68600-30000=38600N.

5.4 External load F=80000N(exceeding preload)

The connection may fail, and the preload and clamping force are difficult to determine.

To sum it up:

No external load: the preload of the bolt is completely converted into the clamping force, and the two values are equal at this time.

The external load is within the elastic range: the deformation of the bolt absorbs part of the load, and the clamping force may be reduced, but the total load may exceed the sum of the preload and the external load.

The external load is lower than the preload: the bolt does not undergo significant deformation, the preload remains unchanged, but the clamping force is reduced.

External load exceeds preload: Further stretching of the bolt may lead to separation of the connector and loss of clamping force, threatening the stability of the connection.

The external load is much greater than the preload: the clamping force may drop to zero, the connector loses the contact force, resulting in separation, and the external load becomes the main force maintaining the connection.

06

Precautions in practical application

When designing and calculating bolt connections, a variety of factors need to be considered, such as material characteristics, environmental factors, etc., to ensure the reliability of the connection:

- Preload torque: Select the appropriate preload torque to ensure that the required preload force is achieved.

- Coefficient of friction: Consider the coefficient of friction between the connecting surfaces, as it affects the amount of clamping force.

Material properties: The material properties of the connected parts also affect the clamping force, such as elastic modulus and yield strength.

- Environmental factors: ambient temperature, humidity, etc., will also affect the pre-tightening force and clamping force of the bolt.

Experience and summary

L.S.ENGINEER Experience and Summary

Through the example analysis of M8×25 class 10.9 bolt, we can see that there may be a difference in the value of preload and clamping force. The preload force is the maximum force that the bolt material can withstand, while the clamping force is the actual force acting on the connected part. When designing and using bolt connections, the difference and connection between these two forces must be fully considered, as well as their impact on the stability and safety of the entire structure.

15061878696